The little engine can rev up to 14,000 rpm if the throttle is open.

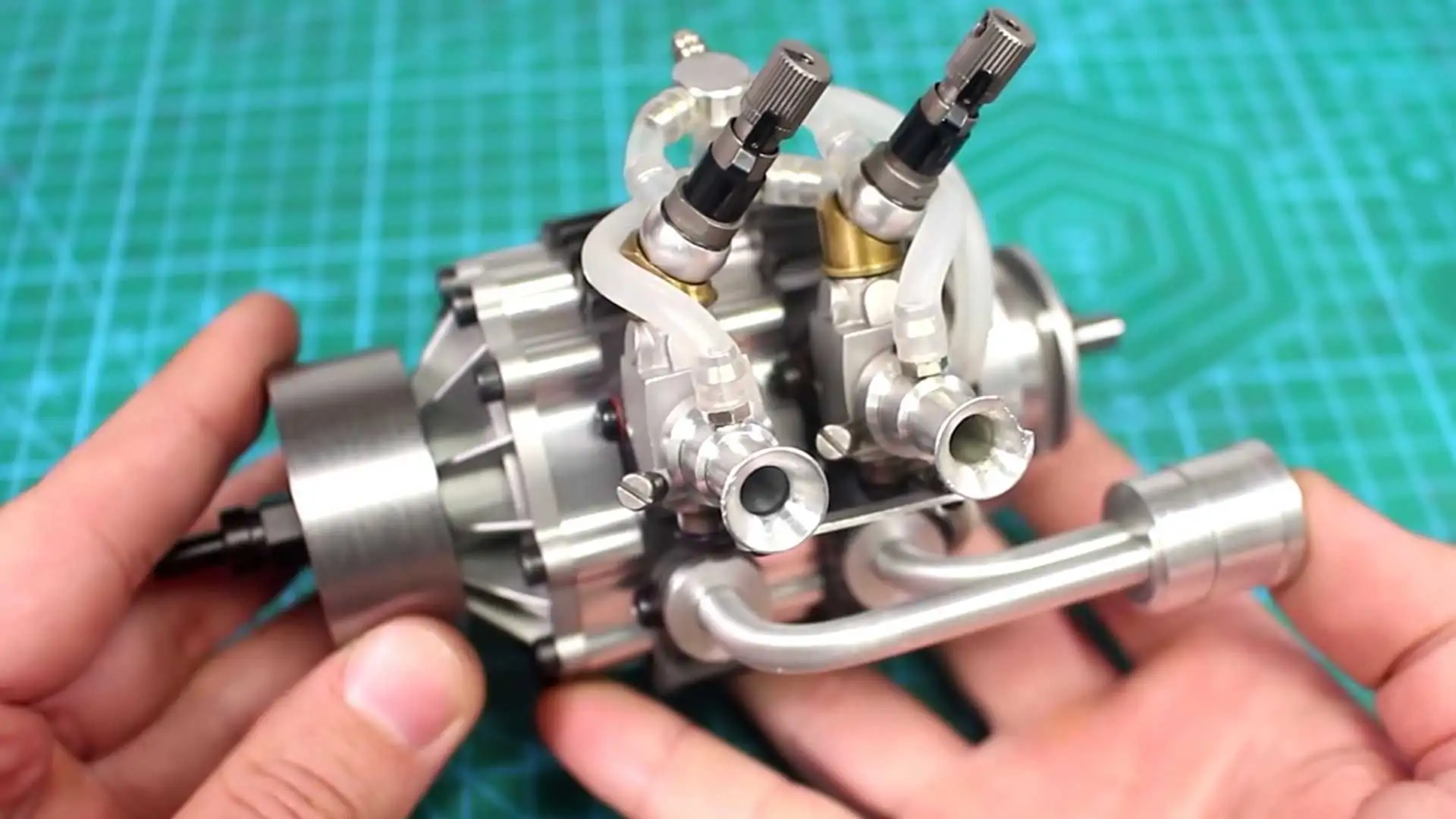

Because precisely machined metal pieces combine to create an engine capable of driving an automobile at high speeds, the internal combustion engine is fascinating. This video, from the JohnnyQ90 YouTube Channel, shows the creation of a small two-rotor Wankel powerplant. You can hold the completed mill in your hands.

This video is part of a series that shows the creation and operation of this tiny, rotary engine. The mill is now almost complete. It has the combustion chambers and rotors completed. This clip begins with the creation and transmission of power to the flywheel via an eccentric shaft.

The problem is that the builder sanded the piece too hard, which causes the eccentric shaft to not fit properly. The creator creates a bushing to allow everything to fit together.

Then he assembles all the internal parts. It is amazing to see how many components are contained in a Wankel engine.

The job is not done yet. The flywheel, intake and exhaust are machined by the builder. To ignite the fuel, he wires glow plugs.

The powerplant will seize after the first attempt to start the tiny rotary engine fails. The powerplant’s single-inlet intake makes it run too low, and so it cannot get started.

This can be solved by switching to a dual-carb configuration. The engine will finally start when this change is made. It makes a sound similar to a small displacement two-stroke motorcycle or a weed cutter.

The digital tachometer displays the Wankel at approximately 4,000 rpm. It spins at approximately 14,000 rpm when the throttle is open.

The rear counterweight is broken at the end. This is an easily replaceable part. The homemade rotary engine can now be put back together.

This video shows how the powerplant will be used in an RC car. The YouTube channel shows that the builder enjoys machining tiny engines and then taking a drive with them.