It could even be saved from being phased out.

As electric cars become more popular, the days of ICE-powered cars are over. Although this is a slow and difficult process that can be reversed, some companies continue to search for an breakthrough that would make internal combustion engines more efficient. Camcon Automotive, a British company could offer a solution.

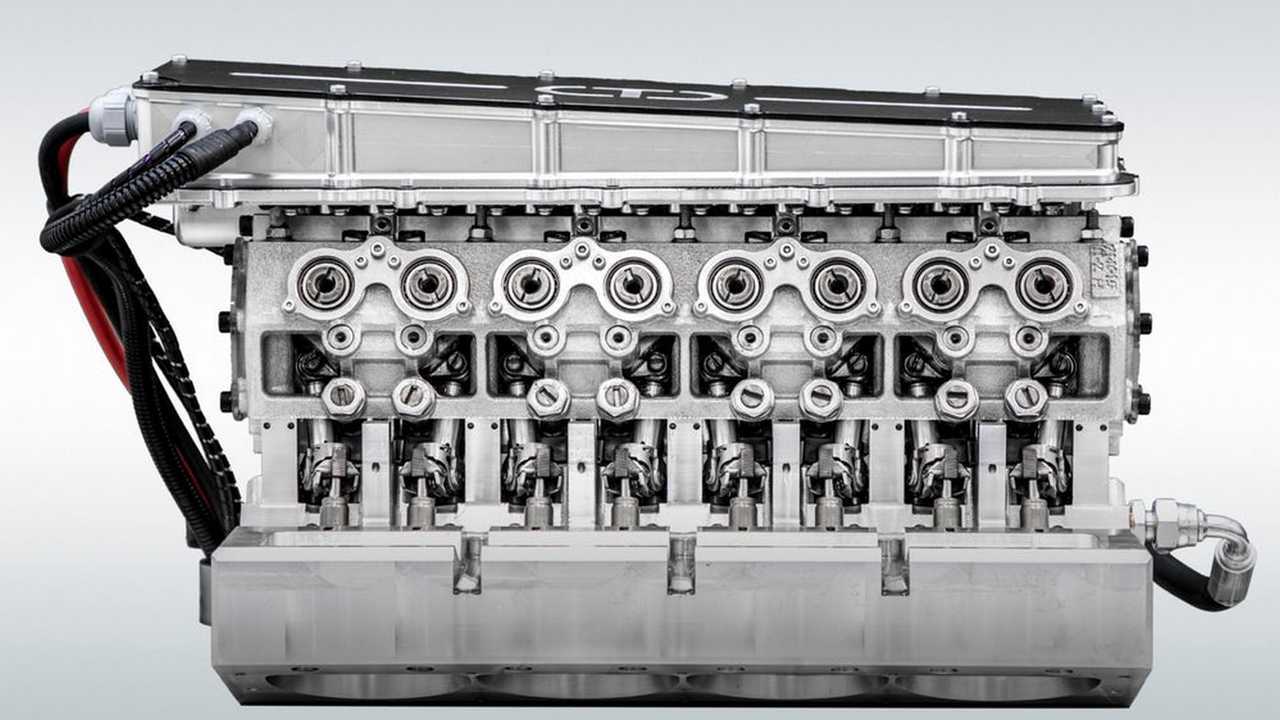

The prototype engine has fully digitally controlled valves, which can be operated independently and are not connected to a crankshaft. Each valve is controlled by its own electric motor, and each camshaft controls an electric motor. This system is called Intelligent Valve Technology by the firm and allows for more precise control over valve lift and duration.

The theory is that the IVT tech should make sure the engine has the right fuel and air mixture for each vehicle. It should, for example, adjust to a more aggressive mixture at full load. However, the engine should be able to deliver maximum fuel economy during cruise conditions.

The system can determine the exact crankshaft position at any time and a rotary sensor makes sure that the valves are open and closed at the right time, depending on the motor’s activity.

“What this means is that we can give the engine exactly how it wants at low revs and exactly what its wants at higher revs and anywhere in between. And you don’t need to compromise at any time,” Mark Gostick, Camcon COO, stated to New Atlas. You can adjust the timing, duration, lift and shape of events. You can do double events. You can alter the profile of the camshaft during each event. In one revolution, you can change your idle setting to 100% throttle. You can do almost anything.”

Camcon reported earlier in the year that it has been tuning and testing its system for thousands hours. It already sees an improvement in C02 emissions when using the Jaguar Ingenium engine to test purposes.