It is customizable, strong, and can be re-used.

Sometimes small changes can make all the difference. This is especially true for large shipping companies, which auto manufacturers are. Consider an automaker such as Ford that produces approximately 2 million vehicles per year. Each car is made up of approximately 30,000 parts. People, that’s a lot parts moving from one place to another, and it costs money shipping them.

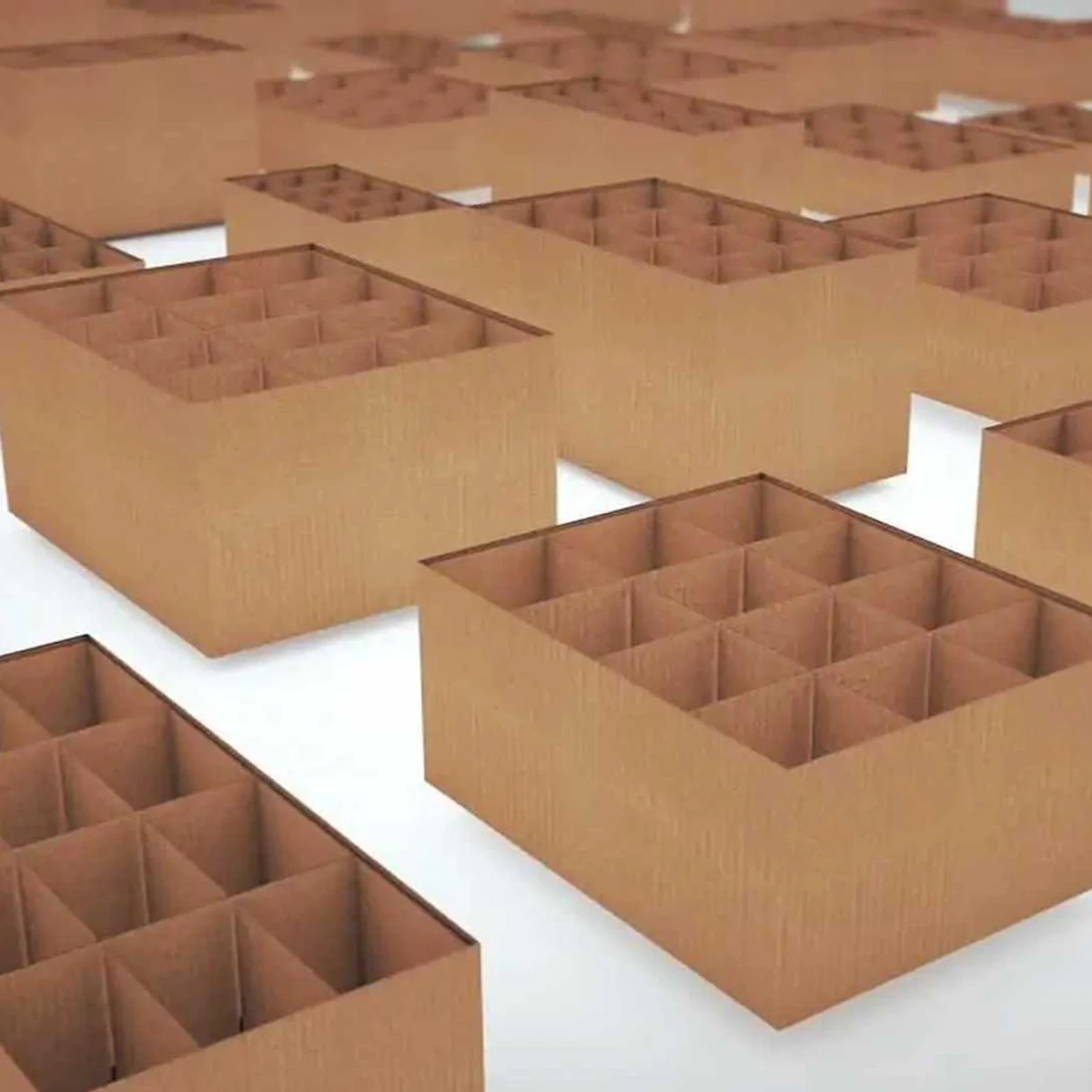

This is where the P2Packaging box comes in. This box looks just like any other, and it is. You can choose from a variety of sizes and the internal partition can be customized to fit into any box. Because of their custom nature, the boxes can be folded down and reused.

The Detroit Free Press reports that P2Packaging boxes are used by almost every major automaker to ship components between their factories and other locations around the globe. This is a good choice considering the delicate nature and fabric trims of some items. The rigid inserts add strength and protection to the corrugated structure. The report also states that boxes can be reused up to 10 times. You can simply fold them up and return them for a new shipment.