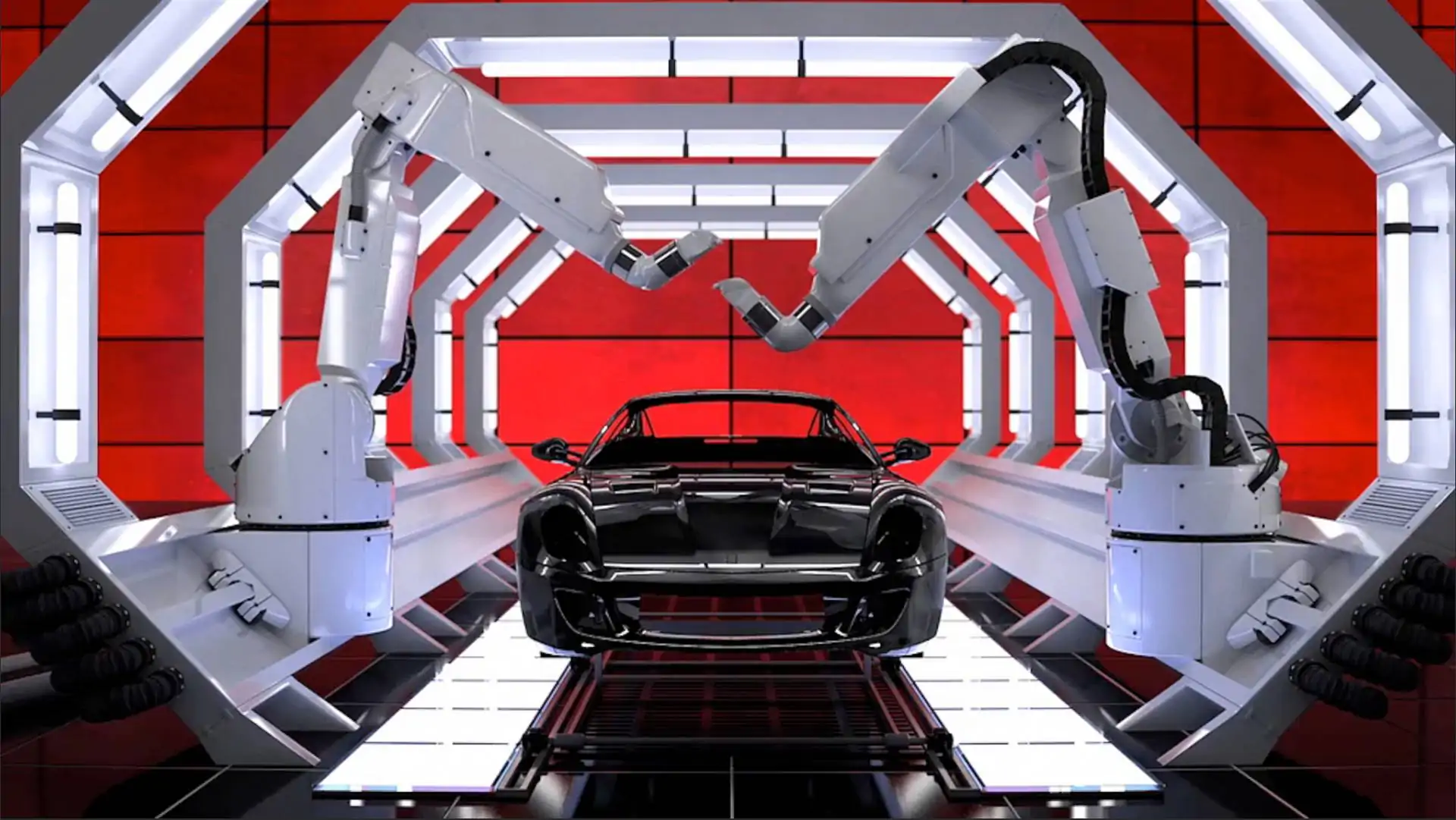

The company is now able to bake carbon fiber and other compost components together with the body shell.

Take a look at a red 25-year-old car and examine the paint. It could be brand new. The paint may have a few scratches and need to be waxed, but it is still serviceable. The paint may also appear faded, with paint flaking and peeling clear coat. It all depends on the automaker. The tough outer shell that protects the automobile’s paint has not always been automotive paint. While some automakers tried new paint techniques, others opted to stick with the established ones. Ferrari, one automaker, is embracing a low-bake paint technology. This allows for lower energy costs and maintains high quality paint – vitally important to a supercar with a rich paint palette.

Ferrari will partner with PPG to become the first automaker in the world to adopt Low Cure clear coatings paint technology. This two-component system includes a specially formulated clear coating. The car can now be baked at 100 degrees, instead of 150. Low Cure resins have a new hardener which increases the paint’s resistance to water and other contaminants.

The lower cure temperature is not the greatest advantage. Ferrari’s new paint technology will enable them to bake carbon fiber and compost parts with the body shell. The automaker will now be able achieve uniform color across all body parts. This new technology allows the company produce no less than 61 base colors. Combining a metallic base coat and a gloss or matte-pigmented clear coat is how this works.

This isn’t the first time Ferrari has used a new paint technology. The company was one of the first to use a water-based paint system in 2004. This and the new low-cure paint will reduce energy costs and increase sustainability.

Ferrari is not known for its poor paint work. However, new technologies can have unexpected results. It’s safe to assume that the automaker did its research before jumping onboard.